Coping Saw Chronicles

The lowly coping saw is often the first introduction to a woodworking saw that a youngster encounters. It was for me. I was eight or nine years old when my father clamped the small block of pine into a vise on his workbench. I had carefully drawn the outline of what was sure to be the fastest Pinewood Derby car ever made. Though he had a nice Delta band saw about four feet away, Dad felt it was important that I do all the work myself. I stood on a stool so I could reach. Up down, up down, with great effort, concentration and determination, my little hands gripped the bulbous handle and I chewed away at my line. First on one side and then the other as the blade wandered to and fro by some uncontrollable force. After what felt like hours, I finally made it all the way around my outline, though by that time there was only a slight resemblance to my original intent. It certainly wasn't perfect, but I did it myself and I was very proud. Much work with files and sandpaper restored the general shape and I was soon off to the races.

My experience with a coping saw must have embedded itself deep within me. It surfaced again about 40 years later when I began to learn about woodworking with hand tools. I discovered there had not been any advancement in coping saw technology in 40 years! Probably 100 or more! Soon after starting Blue Spruce Toolworks, the Knew Concepts saw hit the market with a splash. I used the saw for several years and though it was a nice saw and worked much better than the common coping saw, I wanted something even better, and so the journey began. What follows is the design process of a tool, however the same process can be applied to furniture or other design projects. Here is the abridged chronicle of my improved coping saw design.

Design for me begins in my head and then quick sketches remind me what I was thinking about. No real details, just simple thoughts. Often it will be days, weeks or perhaps months or even years between sketches. At other times volumes of sketches pour forth as concepts and details start to come together.

My first sketch was back in May of 2015. It was just a few lines, a concept for locking blade rotation and a one piece I-beam style frame with overstuffed wood infills. Certainly nothing fancy or well thought out.

Sometime later in May, detail ideas were running through my mind and I put them to paper. Many ideas may not work out but don’t be afraid to capture them. Often a poor idea can lead to a good idea down the road or you can use a portion of an idea to create something new.

With enough sketches and details starting to come together, I started work on a CAD model to begin to analyze size constraints, proportions and details.

The results were.....BORING! A big yawn, that is what I was creating. I was focusing on many of the mechanical details and lost sight of the aesthetics. I mentally crumpled up those ideas and made a three point swish. It was time to let the mind run free for a while; have some fun without worrying too much about reality.

Other priorities happened and I set the project aside for a while and came back to it in August of 2016. Freeing up the mind can often lead to breakthroughs. When you get stuck in a design rut, change it up, work on something else, take some time off, try a clean sheet of paper. It was at this time I began to explore the possibility of not releasing blade tension while rotating the blade. This would allow the saw to be used in a scrolling function; something that no current saw was capable of (that I am aware) and would save time when setting the rotation angle of the blade. Lots of ideas began to take form once again. It is often one detail or design element that precipitates the creative process.

It was time to try and put everything together in a new CAD model. I also started to explore different frame ideas and blade rotation locking details. Don’t be afraid to pull out a clean sheet of paper and try again! And again!

From this stage to the final version there were countless hours of refining, mock-ups, test pieces, prototypes, re-designs and still more refinements. I took an initial prototype to the Handworks show in Amana, Iowa May 2017 for customer feedback. The design was fresh, exciting and well received. A few further refinements were made, and the final version entered into production August of 2017 with a target launch date of November, two and a half years after the initial sketch! Running a business can slow things down. No, it has not actually launched yet. I am waiting on a few parts but it should be ready very soon! It is often said "the devil is in the details" and this is true whether it is a new tool or a new sideboard. Take the time required to work out the details. Set the design aside and come back to it with fresh eyes. What may have looked good yesterday can make you wonder what you were thinking the next day. These refinements will pay off.

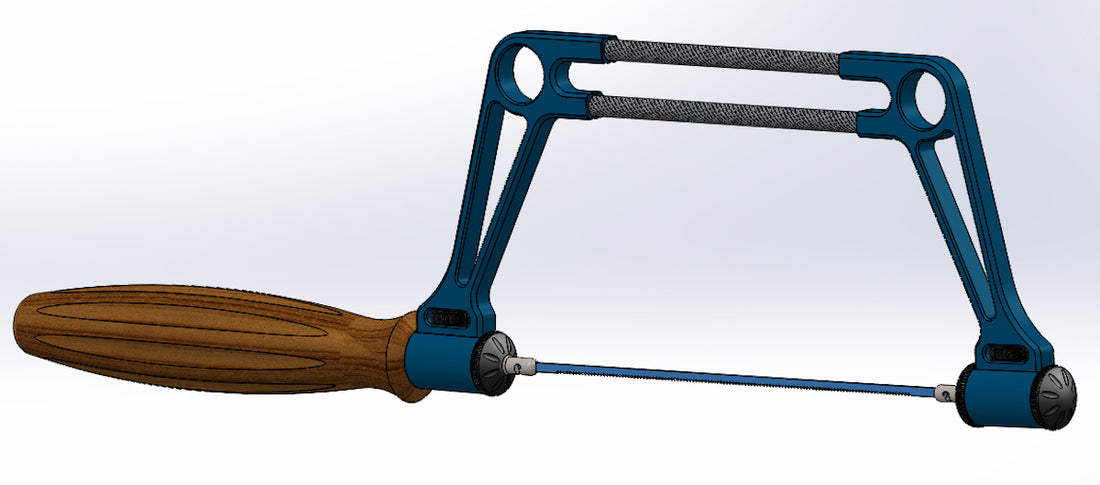

Here is the final CAD model of the production version:

Some parts awaiting assembly:

Highlights of the saw include a very strong multi-piece frame that utilizes ultra-stiff pultruded carbon fiber composite beams, High strength aluminum arms and rotation bosses, stainless steel hardware and gracefully shaped, fluted hardwood handles. The high tension blade can be rotated freely or locked into eight positions with a simple turn of the captured thumbwheels. Blade tension is set with the front cap and locked into place with a tightening of the handle.

Several finishes will be offered for the frame including anodized clear or black aluminum, Blue Spruce green or medium or dark blue ceramic coatings and optional custom colors. Hardware will be available in either black or silver. Handles will be available in figured maple, Africa Blackwood and Cocobolo as well as possible custom options. This will allow you to create your own, personalized saw.

A further advantage of the saw is the ability to convert from coping saw blades to fret saw blades with a simple adapter. This feature greatly enhances the versatility of the saw allowing a great selection of blade choices.

The next steps are waiting for the remaining components to be machined, perform final assembly checks, create the website order pages, finalize packaging, write an instruction manual, and to finally take orders. Like most Blue Spruce Toolworks products, we build to order to allow full customization and may even offer some limited edition options. It has been a long journey and almost 50 years after my first encounter with a coping saw, I am very excited to premier the best coping saw ever made!

When it is finally launch time I will post another blog with all of the options and ordering instructions. For those who follow me on Instagram and emailed me to get on the list for the first 50 saws, I will be contacting you via email before the end of December.

Dave

61 comments

Hey Dave,

If not too late please add me to your list.

I want to be on the list for a saw! I had no idea this even existed until today!

Hallo Dave, what is the reason of removing my message? I wrote you to put my on your list,because the design is so beautiful

Hi Dave, it looks great, please put me on the list for the green one,

and a happy New Year from the Netherlands,

Piet Dijk

This looks amazing. Any room on that list for a Canuck?